Pipe Inspection robot for decommissioning nuclear Installations. These little masters were originally developed to inspect industrial silos and other industrial structures. They measure every sq millimeter of the hundreds of meters of pipes ranging in diameters from a few centimeters to more than a meter wide. They can measure the smallest levels of radiation using Scintillation sensors, photo multiplier tubes GM tubes or any other portable sensor interfaced to it. This process of pre inspection can be carried out at the initial stages before cutting & removing the pipe line for further processing. Time and money are saved during decommissioning nuclear Installations. It can also be used for routine inspection of operating plants. They work both inside & out side of large pipes. Learn more….

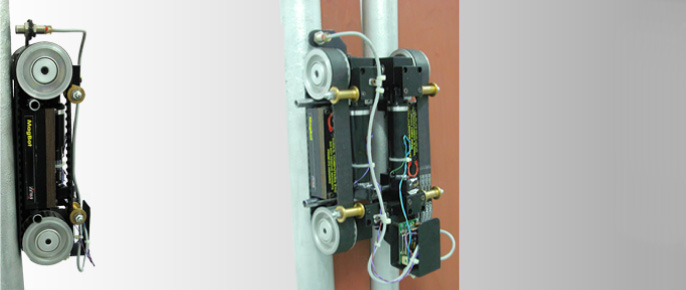

MagBot

Scrubot

Ferromagnetic surface Liquid Tank Inspection / Decontamination Robot, Originally developed for Ship Hull cleaning and modified for the nuclear industry. This robot works in liquid filled tanks or on dry surfaces. Its objective is to scrub the surface gently to reduce the contamination level on the walls. When not scrubbing, sensors can be mounted for detailed inspection.

To reduce the radiation levels in liquid tanks, pressure washing is employed. This involves a human intervention. This robot gently scrubs the internal walls in water, reducing the radiation levels. Being compact and light in weight it can be carried through a man hole no wider than 400 mm in diameter. The scrubbing brushes can be easily replaced after each operation.. Learn more….